Device details

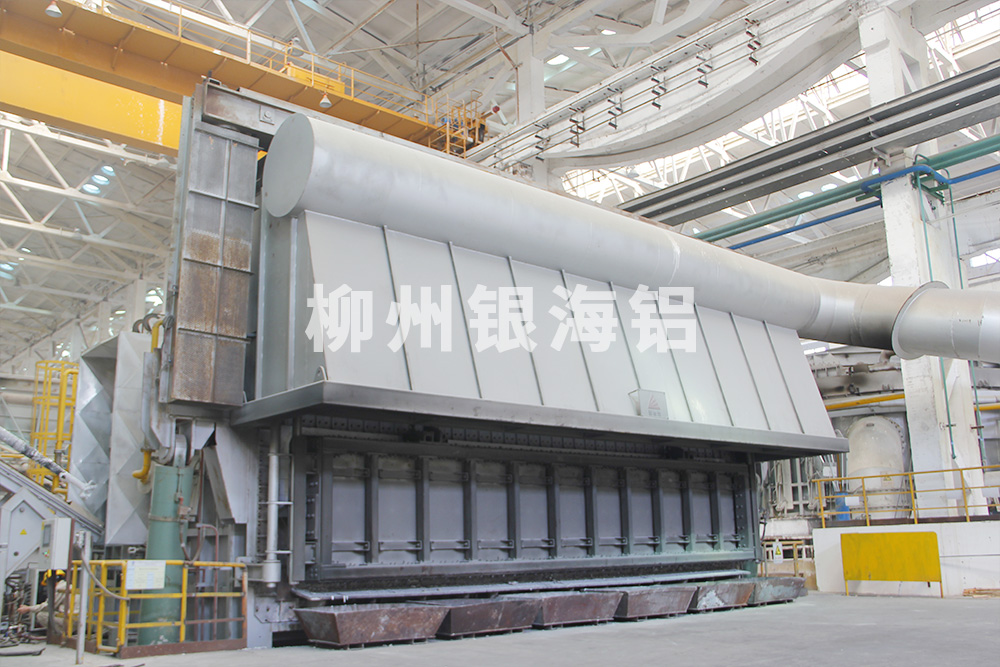

Holding furnace

Main parameters of flat ingot products

|

The thickness of the ingot casting

|

Width of the ingot casting

|

The length of the ingot

|

The biggest ingot weight

|

Maximum number of casting blocks

|

|

520-670 mm |

1150-2520 mm |

3000-7700mm |

32t |

5 |

Equipment configuration:

The company's casting production line adopts 2+2+1 configuration, with a 75t casting, heat preservation and casting production line. A 50T casting, heat preservation and casting production line.

Equipment features:

The smelting furnace equipment is equipped with electromagnetic stirrer to ensure uniform composition.

Advanced RGI and breathable brick degassing systems are equipped for refining in the furnace, and inert gas is used for refining and degassing.

On-line treatment adopts ALPUR degassing system and CFF (foam ceramic filtration) + DBF (deep bed filtration) two-stage melt filtration system to ensure excellent melt quality.

The casting machine adopts imported Honger cylinder traction, laser liquid level control, automatic casting control, the casting process is stable, the ingot size is flat, the ingot surface quality is good.

Quick navigation

Contact us

Address: No.11, Yangtai Road, Yanghe Industrial New District, Yufeng District, Liuzhou, Guangxi Zhuang Autonomous Region

Email: liulvgm@alzco.com.cn

Tel: 0772-3511420

Fax: 0772-3166032

Guangxi Liuzhou Yinhai Aluminum Co., Ltd 桂ICP备15007883号 BY:300.CN

Guangxi Liuzhou Yinhai Aluminum Co., Ltd 桂ICP备15007883号 BY:300.CN